Type:

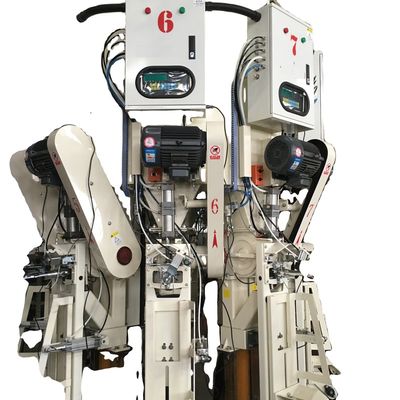

Filling Machine

Applicable Industries:

Food & Beverage Factory, Food & Beverage Shops, Cosmetic Daily Chemical Factory

Showroom Location:

Spain

Condition:

New

Application:

Food, Beverage, Chemical, Machinery & Hardware

Packaging Type:

CANS, Bottles, Barrel, Pouch, Capsule

Packaging Material:

Plastic, Metal, Glass

Automatic Grade:

Semi-automatic

Driven Type:

Pneumatic

Voltage:

/

Dimension(L*W*H):

/

Weight:

154 KG

Warranty:

2 Years

Key Selling Points:

High Productivity

Machinery Capacity:

1000BPH

Filling Material:

Beer, Other, Milk, Water, Oil, Juice

Filling Accuracy:

±1%

Marketing Type:

New Product 2021

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Warranty Of Core Components:

2 Years

Core Components:

Cylinder

After-sales Service Provided:

Engineers Available To Service Machinery Overseas

Style:

Pneumatic Filling

Material:

SUS316L

Filling Speed:

About 6-18 Bottles/min 400ML BOTTLE

Usage:

Cosmetic, Paint, Soap, Detergent Making Machine

Control:

Manual / Auto

After Warranty Service:

Two Years Warranty Video Technical Support

Local Service Location:

Spain

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!