Type:

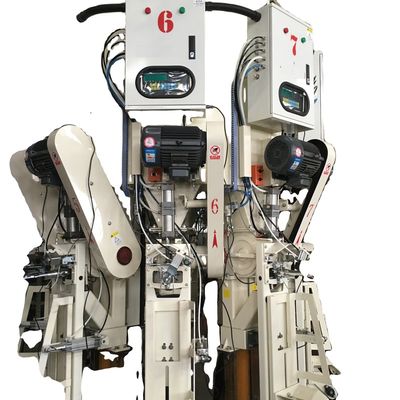

Blister Packaging Machine

Applicable Industries:

Food & Beverage Factory, Medicine

Showroom Location:

None

Video Outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

New Product 2020

Warranty Of Core Components:

1 Year

Core Components:

PLC, Gearbox, Gear

Condition:

New

Application:

Medical

Automatic Grade:

Automatic

Driven Type:

Hydraulic

Voltage:

380v/220

Dimension(L*W*H):

1400*460*950mm

Weight:

450 KG

Warranty:

1 Year

Key Selling Points:

High-accuracy

Product Name:

Dpp80 Blister Packing Machine

Keyword:

Automatic Capsule Blister Packing Machine

Packing Material:

PVC.PP.PET

Capacity:

1200 Plate/h Al-al 2400plate/h Al-plastic

Function:

High Effieciency

Machine Type:

High Frequency PVC Blister Packing Machine

Item:

Blister Packing Machine Change Part

Usage:

Card+blister+card Sealing

PVC Sheet:

Thickness(0.25-0.5)*with 120mm

Max Formed Area:

110*80mm

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

None

After-sales Service Provided:

Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Video Technical Support, Online Support

Certification:

Iso Ce

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!