Type:

Filling Machine

Applicable Industries:

Food & Beverage Factory

Showroom Location:

India, Russia

Condition:

New

Application:

Beverage, Food

Packaging Type:

Bottles

Packaging Material:

Plastic, Glass

Automatic Grade:

Automatic

Driven Type:

Pneumatic

Voltage:

According To Customer Requests

Dimension(L*W*H):

According To Customer Requests

Weight:

10000 KG

Warranty:

1 Year

Key Selling Points:

High-accuracy

Machinery Capacity:

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH

Filling Material:

Beer, Vodka Alcohol White Wine Beer

Filling Accuracy:

±2%

Marketing Type:

New Product 2021

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Warranty Of Core Components:

1 Year

Core Components:

Motor, Pressure Vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

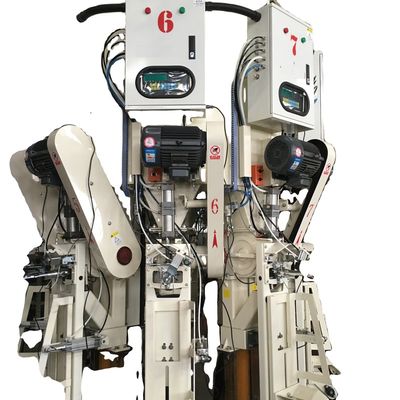

Product Name:

Automatic Bottle Washing Filling Capping Machine

Capacity:

2000-30000bph

Function:

Bottle Washing Filling Capping

Keywords:

Beer Fillng Machine

Filling Speed:

1000bottle-5000bottle/hour

Suitable For:

High Viscous Products

Advantage:

30 Years Experiences

Local Service Location:

Russia

After-sales Service Provided:

Field Installation, Commissioning And Training

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!